Nationally, Most Manufacturers Remain Positive In Their Outlook

Randy Wolken, President & CEO

The National Association of Manufacturers (NAM) released the results of its 3rd quarter 2023 Manufacturers’ Outlook Survey (conducted between August 17 and August 31, 2023). The survey reveals most manufacturers (65%) are optimistic and feel positive about their company’s outlook, despite the tight labor market, challenging federal regulations, and numerous important policy debates in Congress.

Notably, respondents expect sales to rise 2% over the next 12 months. More than 56% of manufacturers predict sales will increase over the next four quarters, with 32% feeling orders will rise at a rate of 5% or more. Medium-sized manufacturers (i.e., those with 50 to 499 employees) and large manufacturers (i.e., those with 500 or more employees) felt the most upbeat in their sales expectations, predicting 2.2% growth over the next year.

Survey respondents expect production to also increase 2% over the next 12 months, up from 1.6% in Q2. More than 53% of respondents forecast output to rise over the coming months. Like sales, medium and large respondents felt more optimistic in their output outlook, expecting 2.2% growth over the next 12 months.

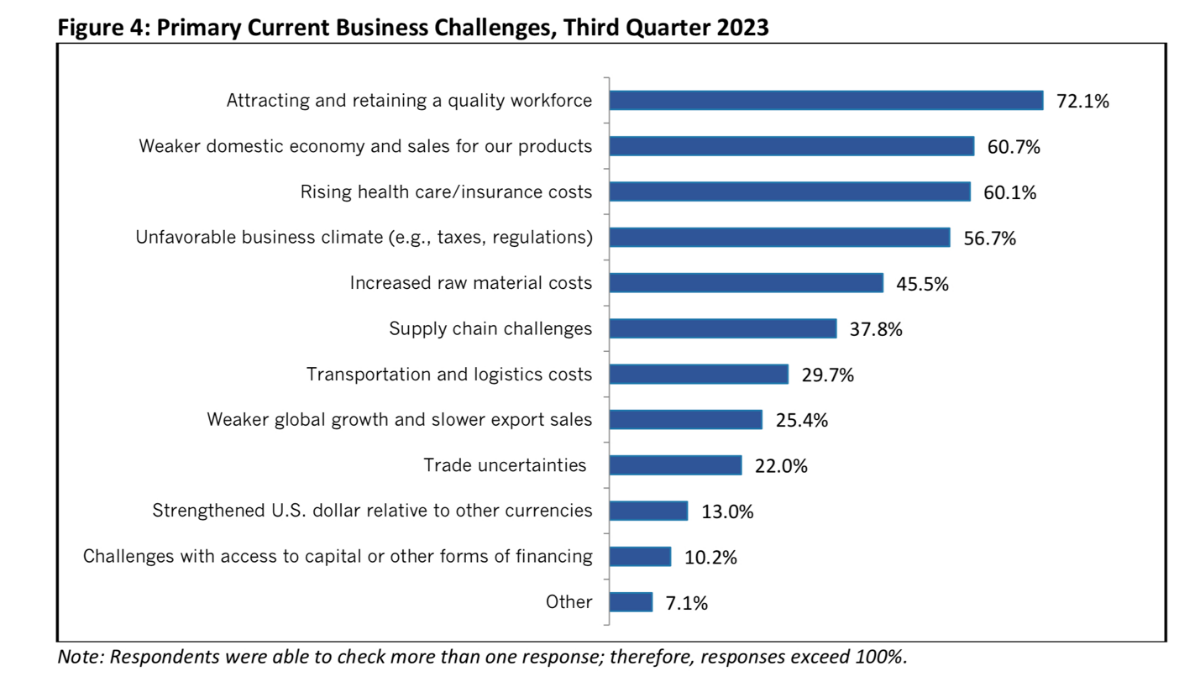

Of course, respondents still expressed concerns and challenges. Of note, concern about an unfavorable business climate reached its highest mark in six years (Q2 2017). As displayed in the chart below, the top challenges facing manufacturers include attracting and retaining a quality workforce (72%), weaker domestic economy (61%), rising health care/insurance costs (60%), unfavorable business climate (57%), increased raw material costs (46%), and supply chain challenges (38%).

In summary, the survey results show strong optimism and expected growth for manufacturers nationally. This is very encouraging and tracks with my discussions with MACNY members who are cautiously optimistic about the future. At MACNY, we are seeing strong usage of our services, and solid attendance at our training and events. Additionally, members continue to pursue ways to hire more staff and invest in capital improvements at their facilities. This bodes well for continued success of manufacturing in Upstate New York.